On-Flight-Inspect - Divisoft Automation & Vision Technologies

Main menu:

- Home

- Company

- Products

-

Vision Sistem

- Vision Sistem

- Robot guidance systems with geometrical cheks and surface inspection

- Non-contact selection systems for geometrical cheks and dimensional inspections

- Non-contact selection systems for geometrical cecks and surface inspections

- Production line inspection

- Hight-precision inspection and measurement systems and machines

- News

- Contacts

- Links

- References

- Vision Sistem

- Robot guidance systems with geometrical cheks and surface inspection

- Non-contact selection systems for geometrical cheks and dimensional inspections

- Non-contact selection systems for geometrical cecks and surface inspections

- Production line inspection

- Hight-precision inspection and measurement systems and machines

On-Flight-Inspect

Home/ Torna su

ON-

Non-

ON-

With the aid of ON-

Please find below some applications already realized:

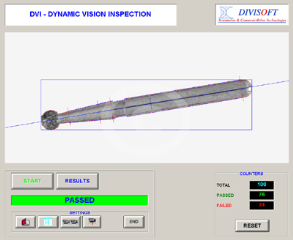

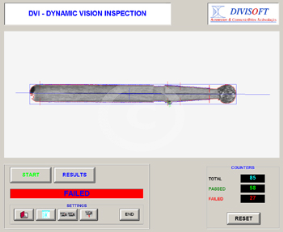

Ball point tips

|

Wood wedges

|

Diamond burs

With ON- |

Screws

ON- |

Within a high production cycle there are a lot of different objects that need to be accurately checked in order to guarantee their respective good quality, and also the need to exclude the defective turning out parts. For these types of components the human control cannot be able to stand such a high production speed and especially be competitive in terms of acceptable costs. |

The object as carried by a high-

The benefits of this system are several: a prompt control over wide sampling, while effecting quick interventions on the production, product history and a drastic reduction in time for size and quality controls. Moreover, thanks to a minimum use of set-

The system may be equipped with maximum six TV cameras with different types of illumination, which allows a 3D analysis. Thanks to its powerful technology different analyses may be effected with accuracy up to ±0,005 mm and a maximum frequency of 10 pieces per second including functions of separation and rejection.

The machine can be used in a total independent way as a control, counting and selection system, as well as be interfaced with a packing or wrapping unit. Concerning the quality control and the traceability of the product, an analysis protocol is available, as well as an additional photographic archive that can be added upon request.